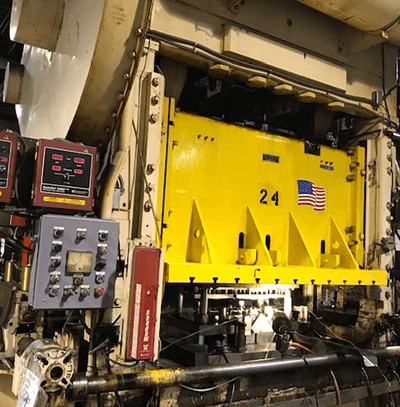

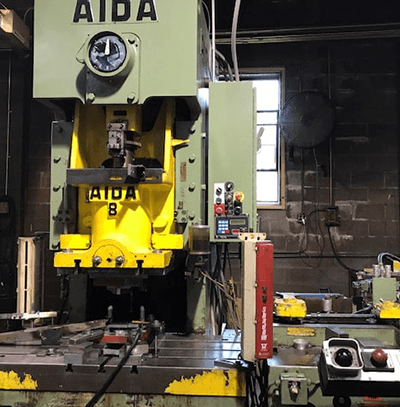

For over 70 years, Gentzler Tool & Die has been a leading tool and die company, delivering high-quality, precision tooling and metal stamping services to industries worldwide. Our comprehensive range of services ensures you get customized solutions for even the most demanding manufacturing challenges.

Specializing in tool and die making, we offer cutting-edge technology paired with a skilled workforce to provide efficient, reliable results that meet your production goals. From design to final production, we’re your partner for superior performance.