Lead Presses

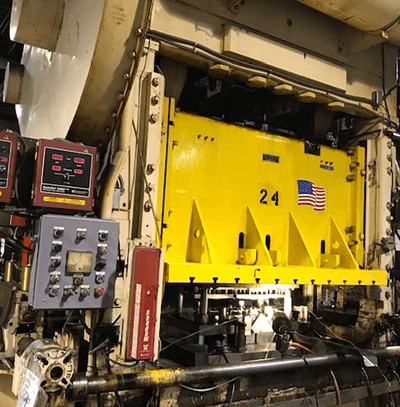

- 1 Minster 250 Ton – 10″ stroke variable speed, bed size 36″ x 80″ with 24″ dual roll feeds

- Bliss 200 Ton – double roll feed & scrap chopper, 12″ stroke, 42″ x 84″ die space

- Warco 200 ton 2 point straight side press, double 14″ roll feed scrap cutter with 8″ stroke 36″ x 72″ die speed, variable speed

- Warco 75 Ton 2 point straight side press, double roll feed and scrap cutter (quick feed) 3″ stroke, 30″ x 48″ die space, variable speed

- 2 Komatsu 200 Ton “C” frame, 10″ stroke, 35″ x 57″ die space, variable speed with in going 18″ servo feeds

- Komatsu 150 Ton “C” frame, 8″ stroke, 30″ x 49″ die space, variable speed with 12″ servo feed

- VERSION 100 Ton 2 point straight side press, double roll feed and

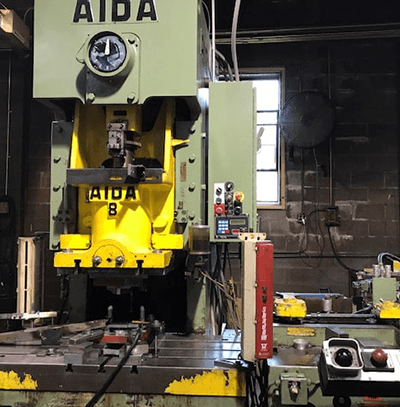

scrap cutter 6″ stroke, 36″ x 72″ die speed, variable speed - AIDA 88 ton 24″x50″ bed, 12″ Dallas servo feed

Secondary Presses

- TOLEDO 225 Ton straight side, lO” stroke, 36″ x 36″ die space

- 2 Aida 150 Ton “C” frame, 8″ stroke, 24″ x 48″ die space single ingoing feed

- Cleveland 110 Ton

- BLISS 90 Ton O.B.I.

- DANLY 75 Ton O.B.I.

- FEDERAL 60 Ton, 6″ Incoming Roll Feed

- NIAGRA SO Ton O.B.I.

- NIAGRA 40 Ton O.B.I.

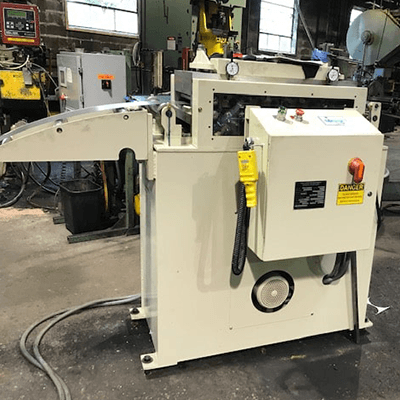

Auxiliary Equipment

- 2 CWP Precision Levelers, 17 Roll .125 max capacity

- 1 Littell 17 Roll x .124 part straightener

- Harper Deburring Machine model 2HA-12

- 2 6000″ Forklift Trucks

- 9″ Time Saver Belt Sander

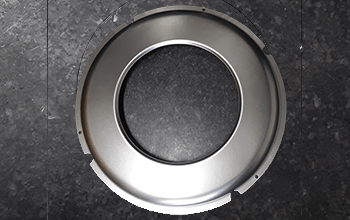

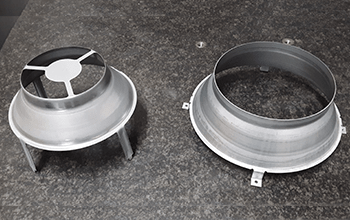

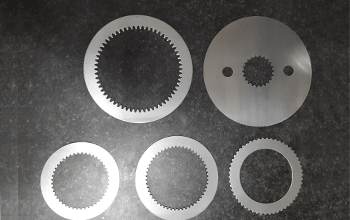

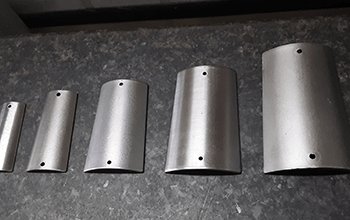

Using presses by manufacturers such as Bliss, Minster and Komatsu, we can easily produce high quality stampings for your needs. By purchasing the best raw materials at the lowest possible price and reducing scrap, Gentzler Tool and Die can produce your stampings at the highest quality and competitive prices.

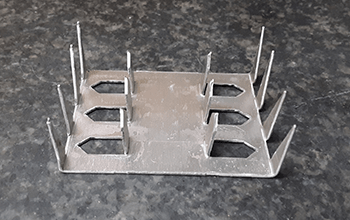

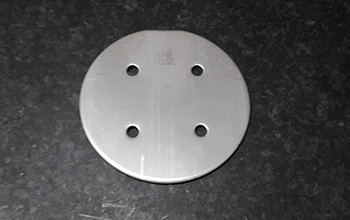

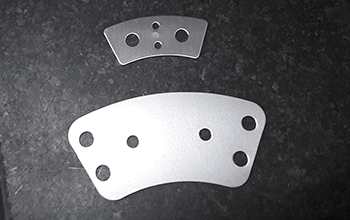

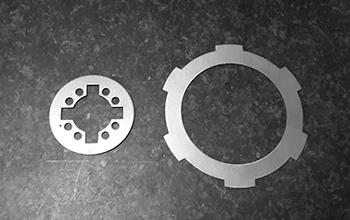

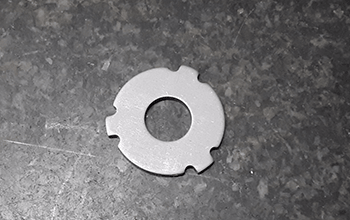

Press Room Part Gallery